Nuestras Divisiones

Trabajamos bajo los más altos y rigurosos métodos de trabajo. Nos involucramos desde el diseño inicial hasta la puesta en marcha final.

ANIVI trabaja para ofrecer una excelente calidad-precio a nuestros clientes. El éxito y la experiencia, son hitos que nos avalan.

Trabajamos con nuestros clientes como nos gusta que nos traten a nosotros, manteniendo en todo momento una relación estrecha y directa durante todas las fases del proyecto.

Los secadores y hornos rotativos para las industrias químicas y de minerales

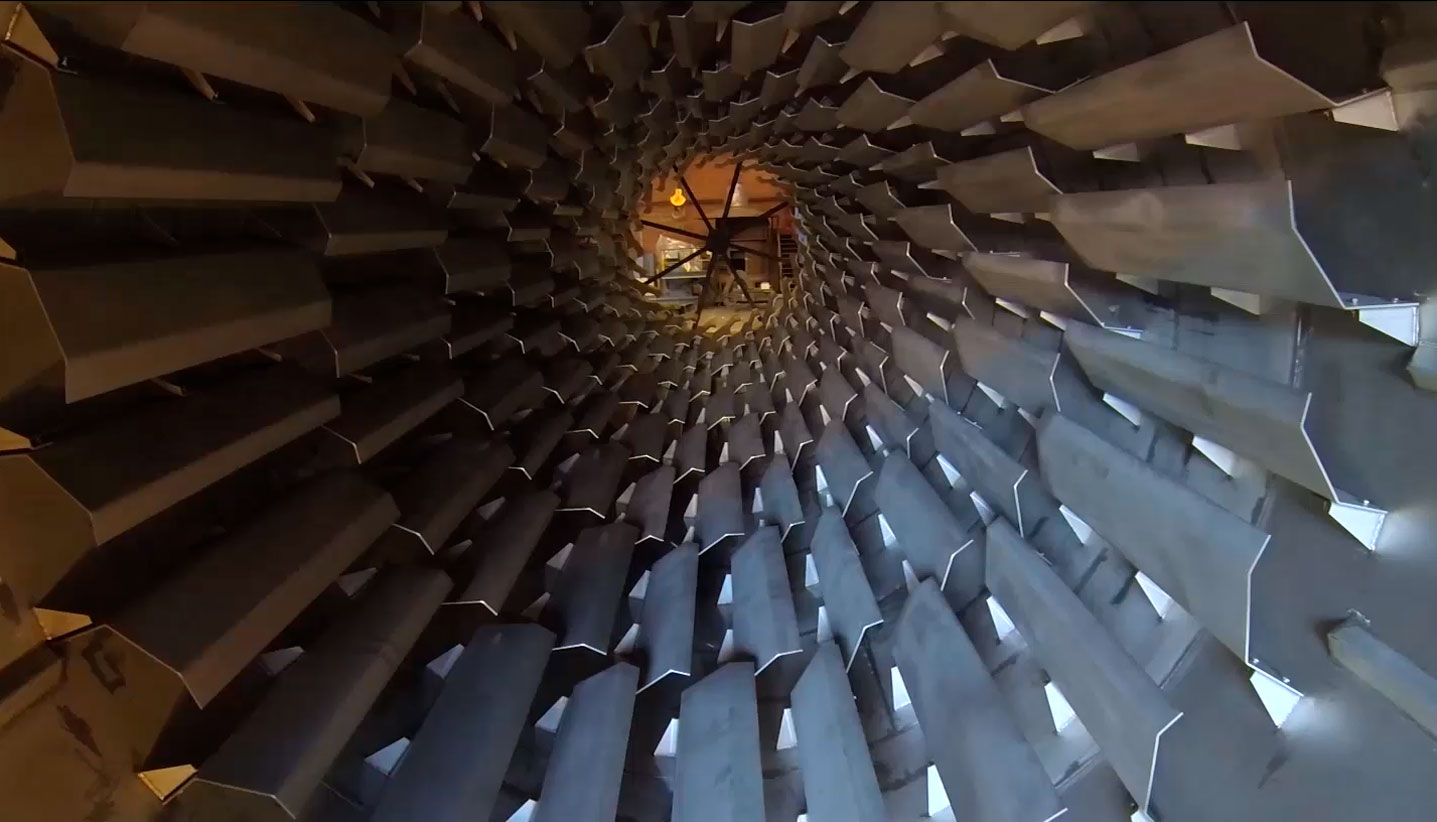

En ANIVI fabricamos sistemas rotativos, principalmente hornos y secadores, para secar, sinterizar, tostar, calcinar, oxidar/reducir diversos tipos de productos, así como incinerar residuos industriales.

Diseño, fabricación y puesta en marcha de plantas de molienda.

Plantas de molienda se utilizan en la industria de minería, minerales crudos y manufacturados, cerámicas, plásticos, procesamiento para materiales de construcción y minerales.

Más de 80 años de experiencia y proyectos en más de 100 países del mundo.

Esta web utiliza cookies para que podamos ofrecerte la mejor experiencia de usuario posible. La información de las cookies se almacena en tu navegador y realiza funciones tales como reconocerte cuando vuelves a nuestra web o ayudar a nuestro equipo a comprender qué secciones de la web encuentras más interesantes y útiles.

Las cookies estrictamente necesarias tiene que activarse siempre para que podamos guardar tus preferencias de ajustes de cookies.

Si desactivas esta cookie no podremos guardar tus preferencias. Esto significa que cada vez que visites esta web tendrás que activar o desactivar las cookies de nuevo.

Esta web utiliza Google Analytics para recopilar información anónima tal como el número de visitantes del sitio, o las páginas más populares.

Dejar esta cookie activa nos permite mejorar nuestra web.

¡Por favor, activa primero las cookies estrictamente necesarias para que podamos guardar tus preferencias!