Treatment of boracic products

Boron Compounds Uses

BORON

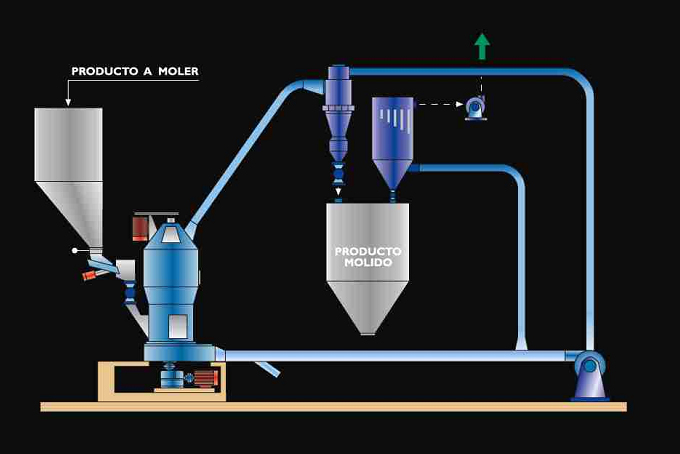

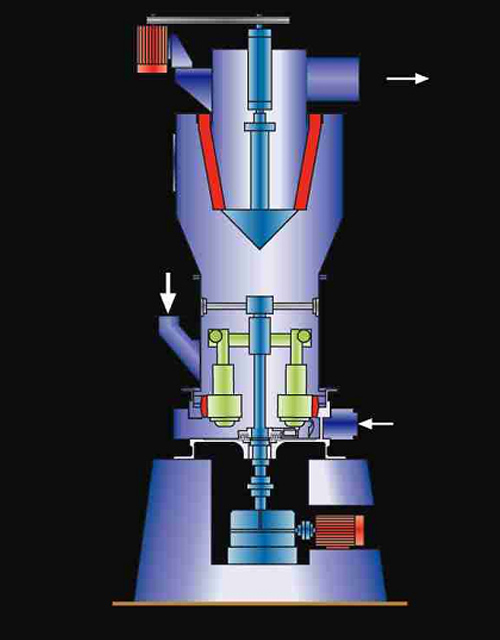

Grinding Plants

For Boron Compounds

ANIVI also offers the possibility of simultaneous drying when the humidity of the product so requires.

With our facilities we can obtain a wide range of granulometry, but for this product the most common are 30 – 250 microns.

Drying Plants

For Boron compounds

Depending on the particle size, ANIVI engineers select the most suitable technologies, maintaining an environment free of dust and particle emissions.