In order to offer the most efficient drying installation, ANIVI Engineers dimension the equipment based on the fundamental principles of drying, as well as the experience of the hundreds of equipment supplied in the past. For this reason, ANIVI is able to supply the most suitable solution for any case in which a drying operation is necessary.

The hot air enters the Dryer from the opposite side to the feed.

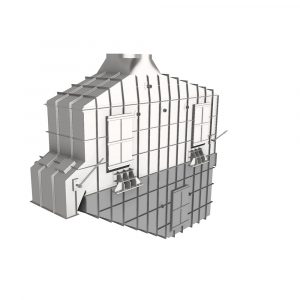

The hot air enters the Dryer from the opposite side to the feed. This system manages to double the residence time of the product for a certain length of the drum. This is achieved thanks to two concentric cylinders through which the product and hot gases circulate, substantially reducing the space required for the installation of a Rotary Dryer.

This system manages to double the residence time of the product for a certain length of the drum. This is achieved thanks to two concentric cylinders through which the product and hot gases circulate, substantially reducing the space required for the installation of a Rotary Dryer. The Dryer shell is heated externally by means of electric resistances or the flame of burners. A key factor when choosing this system is the possibility of regulating the temperature of the Dryer in parts.

The Dryer shell is heated externally by means of electric resistances or the flame of burners. A key factor when choosing this system is the possibility of regulating the temperature of the Dryer in parts.