TYPES OF INDUSTRIAL KILNS

Kilns and their Applications

Rotary Kiln technology is applied in many sectors. There are several industrial operations that can use this technology. ANIVI has extensive experience in the treatment of many products at very diverse sectors.

Apart from the traditional applications in the Cement sector for the production of Clinker and those for the production of Lime for special uses, ANIVI can share experiences with the following products:

Whenever it is necessary to apply the technology of Rotary Kilns, ANIVI is willing to study each case and propose the best solution in technical and economic aspects.

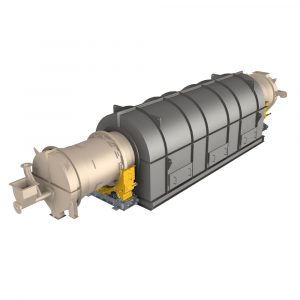

At ANIVI we manufacture rotary systems, mainly kilns, to sinter, toast, calcine, oxidize / reduce various types of products, as well as incinerate industrial waste.

At ANIVI we manufacture rotary systems, mainly kilns, to sinter, toast, calcine, oxidize / reduce various types of products, as well as incinerate industrial waste.