Wollastonite treatment

Uses of Wollastonite

WOLLASTONITA

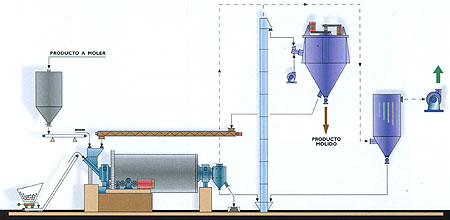

Grinding and Classification Plants

For Wollastonite

ANIVI processes the wollastonite in a ball mill, which may be coated with rubber, flint or alumina, depending on the contamination allowed by the client, the grinding load may be flint or alumina. From the mill, the product goes through a dynamic classifier, which allows to regulate the granulometry without having to stop the installation. The entire installation will have a dust collection through a bag filter to maintain a clean work environment.

With our facilities we can obtain a wide range of granulometry, but for this product the most common are 45 microns.

Drying Plants

For Wollastonite

In many cases, and due to its extraction process or its handling, wollastonite contains moisture that makes subsequent processes difficult. For this situation, ANIVI offers rotary dryers, either fixed or modular that allow the elimination of this humidity, preparing the wollastonite for its next uses.

Depending on the particle size, ANIVI engineers select the most suitable technologies, maintaining an environment free of dust and particle emissions.