Grinding and Drying of Quartz and Silica Sands

Uses of Quartz and Silica Sands

They are used in the manufacture of optical instruments, radios, chemical devices, etc. Quartz sands are used in mortars, concrete mixes, glass making, and for hydraulic fracturing. Siliceous sandstones and quartz are used in the construction industry

Crushing and grinding, it is used in the production of ferromanganese, preparation of boxes for foundry molds, in refractory ceramics, glass industry, sandpaper manufacturing, match scraper, abrasive powders, fine filters, etc.

It is also a major component of the ceramic industry, both in stoneware tiles and in the formulations of frits, engobes and dyes.

QUARTZ

SILICA SANDS

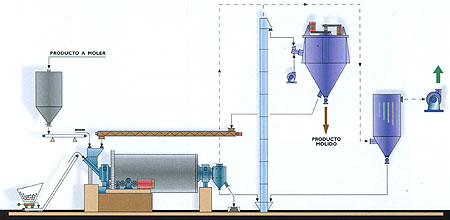

Grinding and Classification Plants

For Quartz and Silica Sands

Usually ANIVI plants obtain granulometries of 98%

ANIVI also offers dryers when supply conditions require drying prior to grinding.

Drying Plants

For Quartz and Silica Sands

Depending on the particle size, ANIVI engineers select the most suitable technologies, maintaining an environment free of dust and particle emissions.

More Information