Zirconium Treatment

Uses of Zirconium

ZIRCONIO

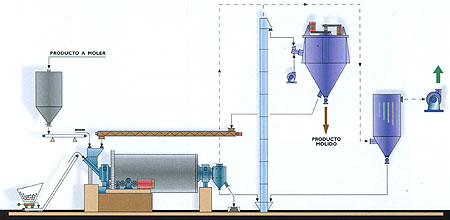

Grinding and Classification Plants

For Zirconium

ANIVI proposes two alternatives, one for zirconium flour with a granulometric cut of 45 microns, and another for the opacifier with a cut of 5 microns.

In both cases a ball mill is used, which is lined with alumina, the grinding load will also be alumina. From the mill, the product goes through a dynamic classifier in the case of flour or a last generation classifier in an air circuit for the opacifier, which allows to adjust the granulometry without having to stop the installation. In the case of the opacifier, the product is collected in a bag filter. The entire facility will have dust collection to maintain a clean work environment.

With our facilities we can obtain a wide range of granulometry, but for this product the most common ones are 45 microns for the flour and 5 microns for the opacifier, with an average particle size of around 1.5 microns.