Non-Abrasive Products Grinding

Its typical use is the grinding of semi-hard and non-abrasive minerals, being capable of grinding to fines between 25µ and 150µ. When the product has a little moisture, it can be dried simultaneously while grinding with the addition of hot air.

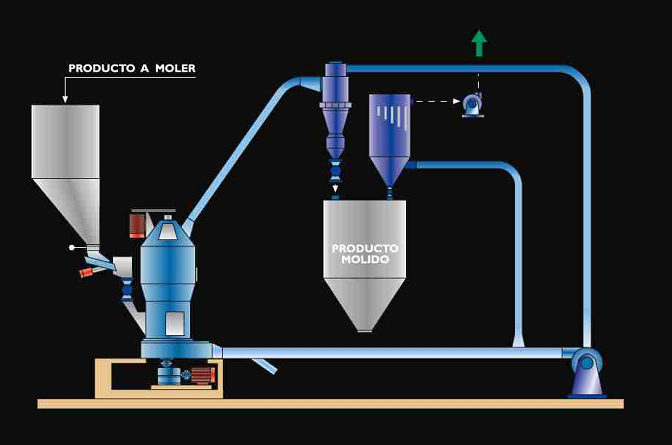

Functioning

The feeding system adjusts to find the optimum working point with a regular feeding. The grinding is carried out by the pressure produced between the rotating pendulums and the track. The pressure can be modified by varying the turning speed of the machine.

Simultaneously, the main fan blows air into the grinding chamber, dragging the fines that are continuously being produced. The dust-laden air jet is drawn into the Classifier, located in the upper part of the Mill, where the coarse particles are rejected and the dust-laden jet passes to the Cyclone, where the classified product is decanted. This vein is blown back into the Mill, in this way the closed circuit is produced: Mill-Classifier-Cyclone-Fan-Mill.

When treating products with humidity and hot gases are added, it must be taken into account that the water vapor passes through the Bag Filter, therefore, to avoid condensation, all hot areas must be insulated