Abrasive Products Grinding

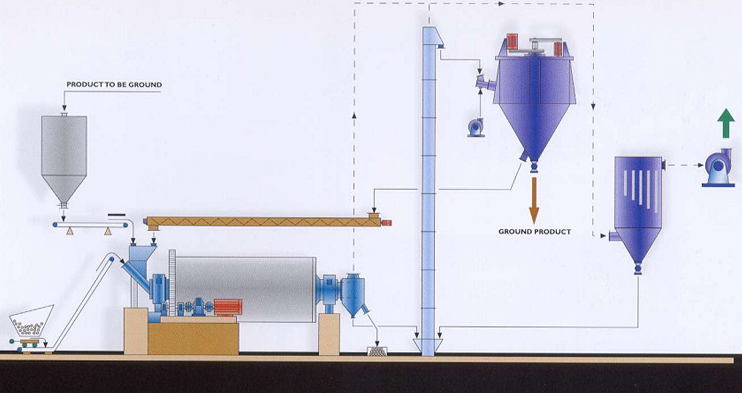

ANIVI – STURTEVANT Plant

Functioning

When materials destined for ceramics are ground, the mill works with shielding and non-polluting loads, using linings of Flint, Alumina or Rubber. When metallic contamination is not decisive, shields and steel balls are used.

The grinding load is fed into the mill automatically without the need to stop or open the mill. At the exit, a sieving system removes the broken balls from the circuit. Usually, the mill has a crown-pinion drive and is supported by anti-friction bearings with continuous and automatic greasing, and protected with safety systems. The mill receives material to be ground from the Hopper, the rejects from the Classifier and the feed.

The Classifier, an essential element in this type of plants, is responsible for obtaining the desired product fineness at all times. It is a very experienced and safe machine, with minimal abrasion and maintenance problems. Fineness changes are made from the control panel without the need for installation, which allows for great flexibility to produce different qualities of products. The work environment is clean, ensured by a capture system using an automatic cleaning bag filter.